Circuit Board Conformal Coatings – Removal Can Be A Disaster If Not Done Correctly.

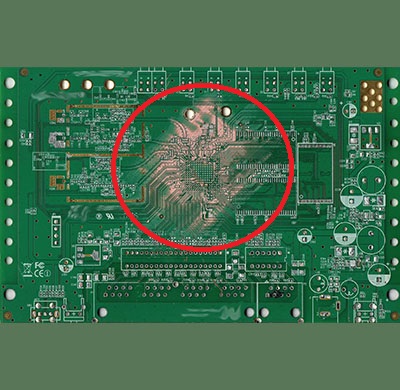

A Danfoss FCD 3.3Kw (5Hp) VSD arrived recently from a client for repair. We were told that the client’s maintenance crew attempted a repair on the circuit board but did further damage trying to remove the conformal coating. On dismantling, we found the circuit board was badly scratched and a few electronic components broken. Unfortunately their heavy handed trades person almost destroyed the PCB by firstly attempting to remove the coating mechanically.

So what is Conformal Coating you might ask? It is a protective layer of film applied over circuit boards and is usually a two-pack resin, an acrylic resin, silicone or Parylene. The coating helps prevents corrosion, mechanical damage, etc. and must be removed to diagnose and replace faulty electronic components. An appropriate chemical that is inert to the circuit board and components, or light heating, is the best way we have found to remove the coating. Scrapping and sanding is strongly discouraged.

After many years, Rom-Control has had to developed specific techniques with non hazard chemicals to remove the coating. So do your research before reaching for a sharp knife or sandpaper.

After much re-construction, we did clean and re-build our client’s VSD thankfully as this particular drive was discontinued many years ago. Now their machine is up and running at full speed.

If you wish to discuss further, contact us at rc@rom-control.com.au or send us a message at https://www.rom-control.com.au/contact-us/ to discuss.