Evolution Mining CASE STUDY

Power Electronic Building Blocks (PEBBS) Repair and Refurbishment - Significant Savings

About the Company

Evolution Mining is a mid-tier Gold Mining company with various mines around Australia. With significant plant investment, the Cowal mine in New South Wales produces 250,000 ounces of gold per annum and is one of Evolution’s major producers. The company’s production equipment includes a large number of electrical/electronic equipment which is critical in maintaining high production uptime. As some of the equipment is no longer supported by the OEM, it is important for the company to setup a reliable alliance with companies that can help reduce the significant maintenance costs associated with the repairs.

Summary

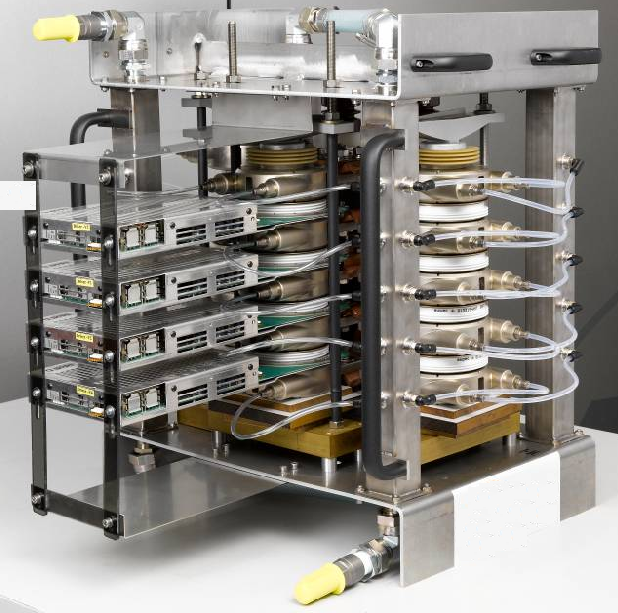

The Evolution Mining production facility includes four Reactive Power Compensator (RPC) units, the smallest being 10 megawatts, and each incorporates a large scale PEBB (Power Electronic Building Blocks) assembly.Due to the remoteness of the site, the quality of power supply can deteriorate and negatively affect production uptime (brow outs, sags and swells, surges). The RPC units help maintain a clean power supply to the critical equipment in the mine. To accomplish this, these complex RPC incorporate highly sophisticated power electronic systems, control and system protection.

Due to the harsh operating conditions and the remoteness of the plant, the PEBBs suffer additional stress caused by environmental conditions such as temperature, dust and moisture resulting in the PEBBs failing unpredictably. Replacement costs of these specific PEBBS can be extremely high but usually, these PEBBs are not available due to obsolescence. Evolution Mining’s only real alternative was to find another solution that could provide a reliable and economical fault finding service that included, repair and refurbishment of the PEBBs.

Evolution Mining sourced Rom-Control as the only repairers of the PEBBs in Australia having the knowledge and expertise to manage and maintain the equipment. Rom-Control backs up their professionalism with an excellent reputation in repair and refurbishment of electrical/electronic equipment.

Being ISO 9001 certified, the quality of the service Rom-Control would provide would include putting appropriate systems and processes in place which was important for Evolution Mining.

Evolution Mining requested the services of Rom-Control to repair and refurbish the PEBBs on a rotating basis to ensure the reliability of their production and provide the confidence that the on-site spares are trusted and functional when required.

Issue to be resolved

Rom-Control reviewed the design and the electronic components incorporated on the PEBBs, particularly how the three IGCT’s (Integrated Gate-Commutated Thyristor) were designed and constructed, to ensure the correct parts and an appropriate process would be followed to refurbish each PEBB. Even in the absence of manuals or schematics, Rom-Control were able to develop a repair procedure and testing regime to ensure quality assurance met the very tight and stringent requirement.

Action

Each PEBB assembly consists of three Integrated Gate-Commutated Thyristors (ICGTs) banks which Rom-Control completely dismantles, tests each component (using state of the art Automated Testing Equipment) and then re-assembles. Many of the discrete components are replaced with new to ensure reliability when installed back in the field. Each PEBB unit is re-tested based on our ISO 9001 certification by completing a full component functional and signature analysis. Once the PEBB passes the Quality Assurance stage, the unit is returned to the client.

Result

The refurbished PEBBs are installed back into the RPC’s and to date there is a 100% success rate. Evolution Mining are able now to minimize their downtime and have significantly reduced their maintenance cost by tens of thousands of dollars per annum. Enquiries regarding this Case Study

Adrian Ciorogaru Ph. 1300 766 287