Film Crew Unwittingly Solves Our Circuit Board Issue

Recently we invited a film crew to our premises to make a promotional video on how Rom-Control repairs and refurbishes industrial electronic control systems. The concept for the video was to illustrate how we fault-find issues on complex circuit boards that have been in service for many years.

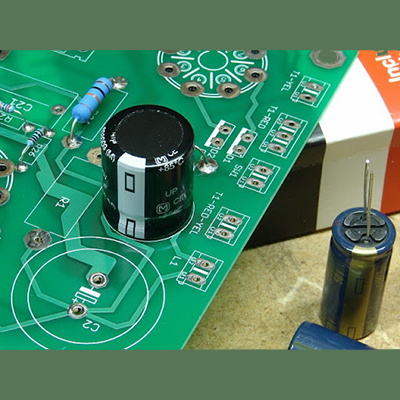

From our ‘technically difficult to find the fault’ pile of circuit boards, we found an integrated Power Control Unit (PPU) that would be perfect as the subject matter for the filming. We then proceeded as normal through our repair process with the film crew in tow. Eventually, we had the Unit on our workshop bench cleaned, dismantled, and fully diagnosed. It was found that one electrolytic capacitor had failed which we did replace, but failed again during our testing. With the faulty part identified and replaced, our Electrical Engineer Hiren was ready to turn on the PCU.

Before Hiren could flip the switch, the film director suggested wouldn’t it be funny if something ‘blew up’ harmlessly while the cameras were on. Hiren’s eyes lit up and now knowing this circuit board intimately, he said, ‘I can do that!’ He then proceeded to remove the new electrolytic capacitor and turned it the other way round to make it reverse polarity. This would ensure that the capacitor would blow up with a loud popping noise but not be unsafe, nor will it damage anything on the circuit board. The film crew was delighted and zoomed in to make sure they caught all the action.

Hiren then flipped the switch to turn on the PPU. No noise, no smoke, nothing. Amazed, Hiren attached the test equipment that showed the PPU was working properly. This does not make sense!

After a lengthy examination of the board circuitry, Hiren realized what had happened. Each circuit board is screen-printed to show what and where the components are to be installed and indicate their proper orientation. For this new capacitor, the board’s screen printing showed the placement backward. After further rigorous testing, Hiren confirmed this to be true and was then able to confirm why the original repairs were not successful. This was an amazing fate of luck and potentially saved us many more hours of frustrating investigation.

Not wanting to disappoint the film crew, Hiren found another simple board to simulate the capacitor blowing up (a lot of noise and smoke, no risk to health or damage). Everyone was happy that day including the client when we returned the PPU in excellent working condition.